Brightwin Big bottle rotor pump Filling Capping muti-function Labeling Machine Line For A Customer From USA

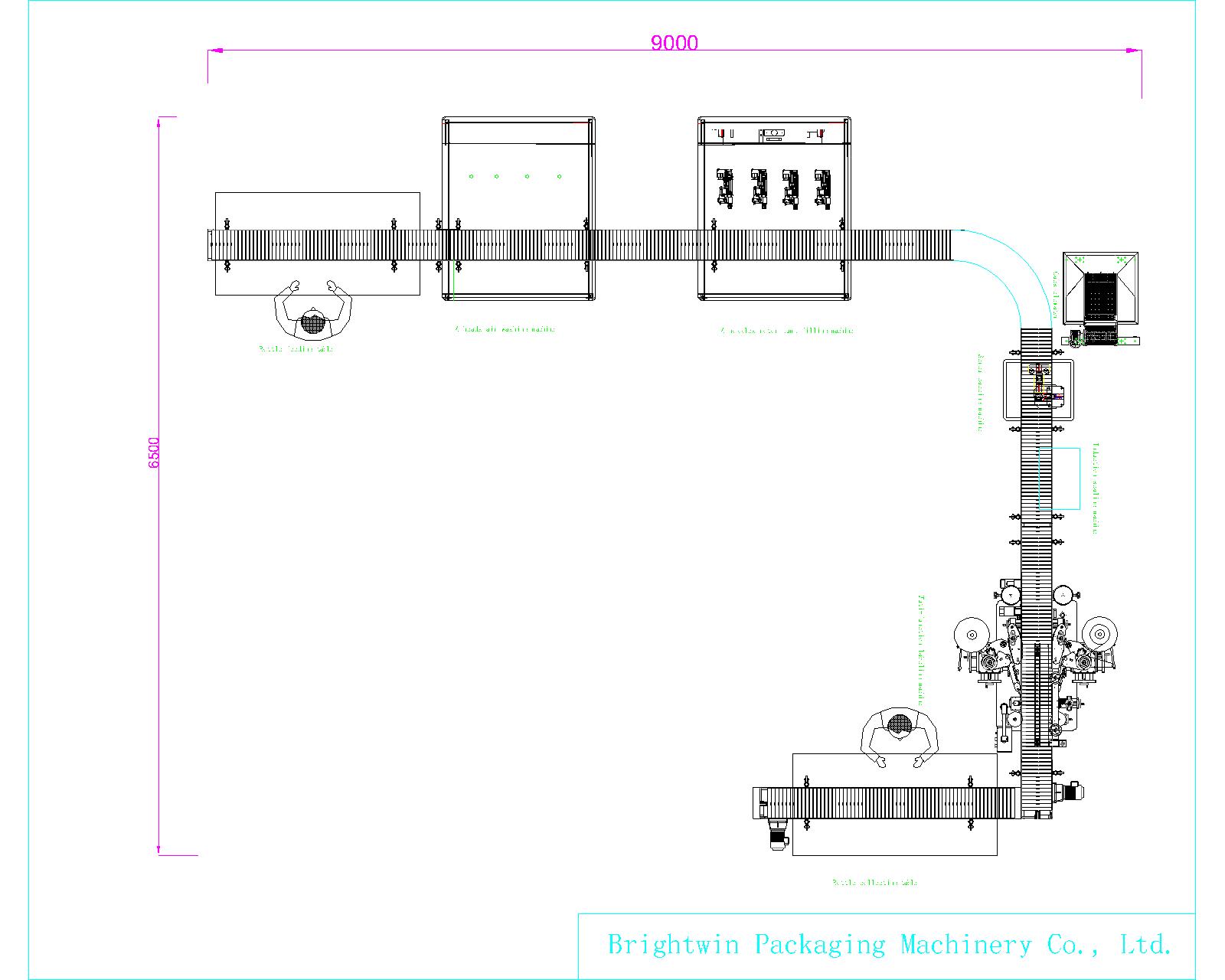

Washing reagent liquid automatic rotor pump filling elevator feeding caps servo screw capping induction sealing muti-function labeling machine line. The whole line was assembled bottle feeding table and collection table to be an automatic packaging line. The line is suitable for 4 size bottles through adjusting some parts and change some parts. The line was desigened to be "L" type layout according to customer's factory size.

Workers place empty washing reagent liquid bottles on the conveyor in the middle of the table, conveyor runs will take the bottles go with it to the next station. No matter the bottles' shape, square bottles, round bottles, special bottles, all standable containers can adop this feeding method.

This washing reagent liquid air washing machine adopts high pressure gas to blow the bottles' interior to clean the bottles. It's adjustable for different size bottles.

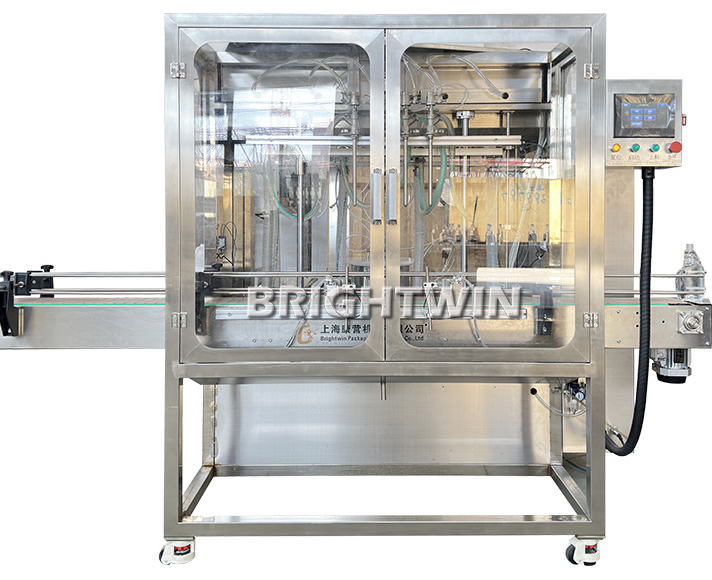

The washing reagent liquid filling machine adopts rotor pump to metering the filling volume, the filling volume can be set on the touch screen. This line washing reagent liquid filling machine is adjustable for different size and shape bottles, no need to change any parts. Operat easily. We designed 4 nozzles washing reagent liquid filling machine according to customer's capacity need. How many nozzles can be customized based on different capacity reqest.

This screw capping machine adopts caps elevator to feed caps one by one, elevator is suitable for all 4 kinds of the caps. Caps are lifted by the elevator and will slid down through the caps track, and wait in line from the exit of the cap track. Capping head is movable, when enough caps are ready, capping head goes catch one from the exit of the cap track, and back to origin position to wait for filled bottles, once a bottle arrives, capping head down and screw the cap tightly on the bottle mouth.

Electromagnetic induction aluminum foil sealing machine is a new sealing machine with intelligent dual cooling system developed by our company, and it can choose to have no aluminum foil automatic elimination function.

In the production line, when the container with aluminum foil on the screw cap passes through the induction probe of the machine, under the action of high-frequency electromagnetic field, huge eddy current will be generated instantly, and the adhesive film on the lower layer of aluminum foil under the bottle cap will be melted and bonded with the bottle mouth, so as to achieve the goal of non-contact quick sealing.

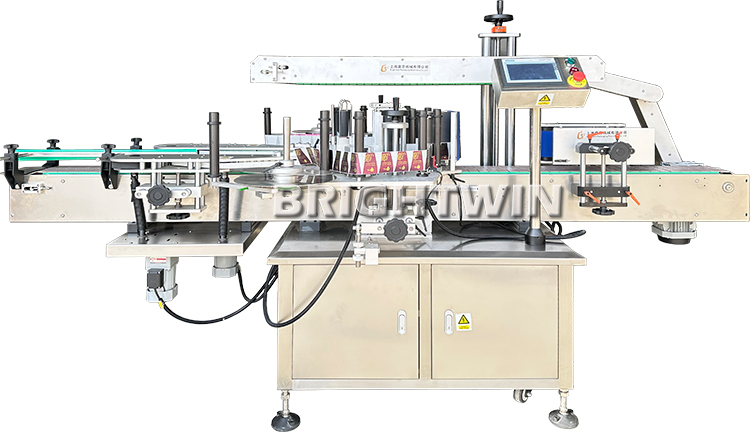

Capped bottle come with the conveyor, will be sticked with labels on requested surfaces. When filling square bottles, choose two labeling heads work, the labeling machine will stick two labels on the both sides of the bottles at the same time. When filling round bottles, choose one labeling head work, the labeling machine will stick one label on the round bottles, then the rotating sponge will rotate the round bottles to roll the labels tighten on the bottles' body as request.

Finished bottles come with conveyor, will be collected in this table, waiting for workers to do next packaging movement.

| Program | Liquid reagent rotor pump filling screw capping induction sealing labeling machine line |

| Filling nozzle number | 4 |

| Capacity | 480bph for 2.5Gallon volume |

| Bottle shape | Squar and round plastic bottles |

| Accuracy | ≤±1% |

| Air pressure | 0.6-0.8MPa |

| Voltage | 220V Single phase |

| Power | 11KW |